|

Testing For War

General

Motors Milford Proving Ground in

World War Two

Milford, MI

1924-Current

This page updated on

4-22-2021.

The GM Proving Grounds at

Milford, MI, or more commonly known simply as "Milford" to those that

work within in General Motors, was used extensively by U.S. Army

Ordnance during World War Two. It acted as an auxiliary test

ground to the military's main proving ground at Aberdeen, MD.

Within the 1,000 acres and 19.652 miles of test track and roads, Milford

tested over 900 military vehicles from all manufacturers to make sure

they would perform in combat as needed during the Second World War.

Milford also had environmental chambers to test vehicles under extreme

temperature conditions. For

this work, it received the Army-Navy "E" award five times.

How cool is this? An M36 Jackson tank

destroyer is nearing the crest of the 25% grade gravel hill as a T26E1

starts up the grade. Image added 1-6-2021.

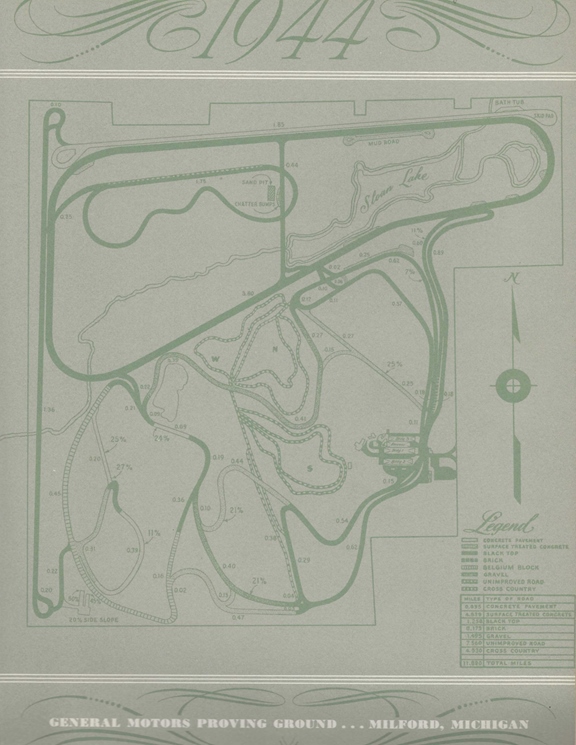

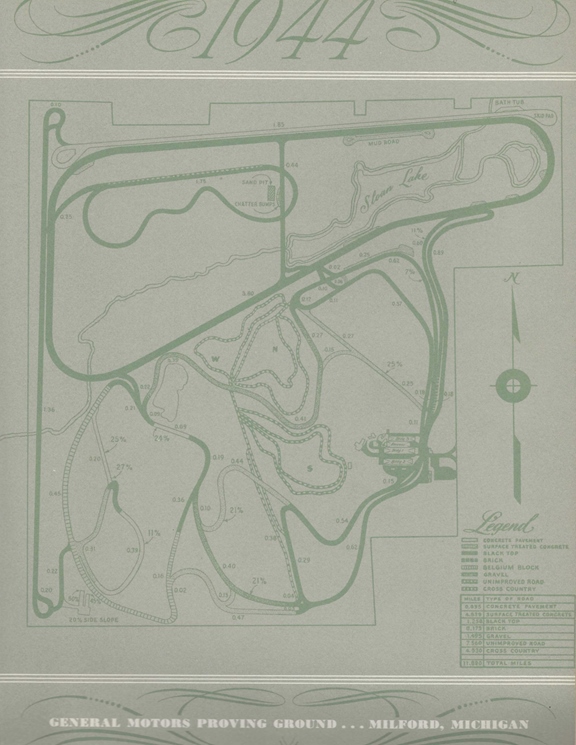

This map shows the layout of the General

Motors Milford Proving Grounds during the Second World War. The

layout has changed significantly since the end of the war. There

is now 4,000 acres and 130 miles of roads and test track at the facility.

Image added 1-6-2021.

|

Summary of Road Types and

Mileages from the 1944 Map |

|

Miles |

Types of Road |

|

0.095 |

Concrete Pavement |

|

4.539 |

Surface Treated Concrete |

|

1.258 |

Black Top |

|

0.175 |

Brick |

|

1.495 |

Gravel |

|

7.560 |

Unimproved Road |

|

4.530 |

Cross Country |

|

11.890 |

Total from map |

|

19.652 |

Actual Total |

Author's Note:

The map gives a total mileage of 11.890 miles. I found these

numbers added up to 19.652 miles.

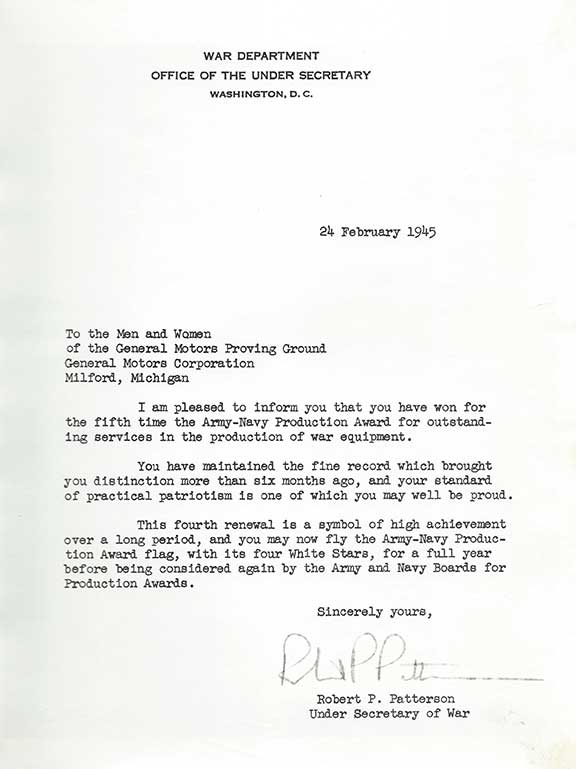

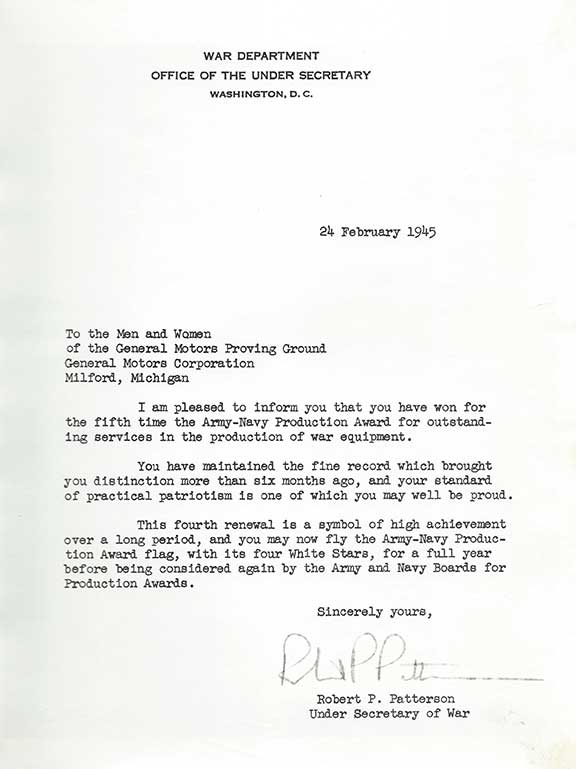

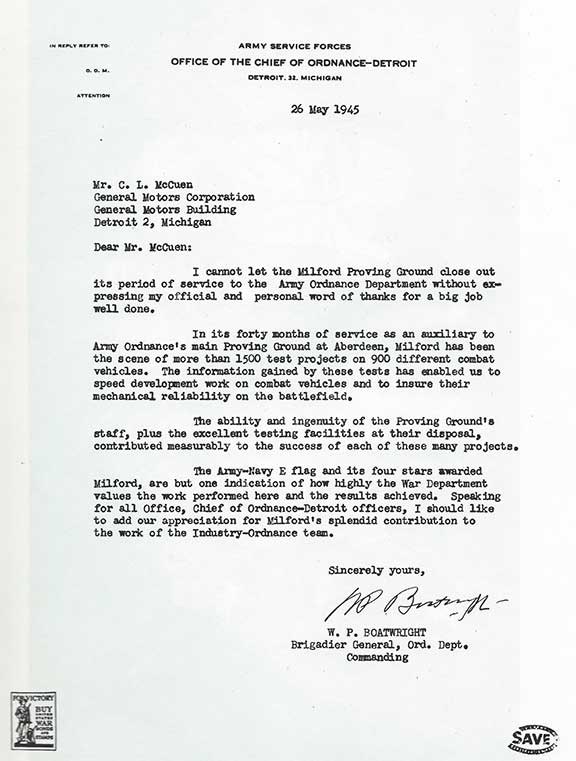

The GM Proving Ground won the first Army-Navy "E" Award

on December 19, 1942. The letter below dated February 24, 1945

notified Milford that it had won its fourth star.

In this letter dated February 24, 1945,

Robert P. Patterson, Under Secretary of War informs the employees of

the GM Proving Grounds they have just earned their fourth star.

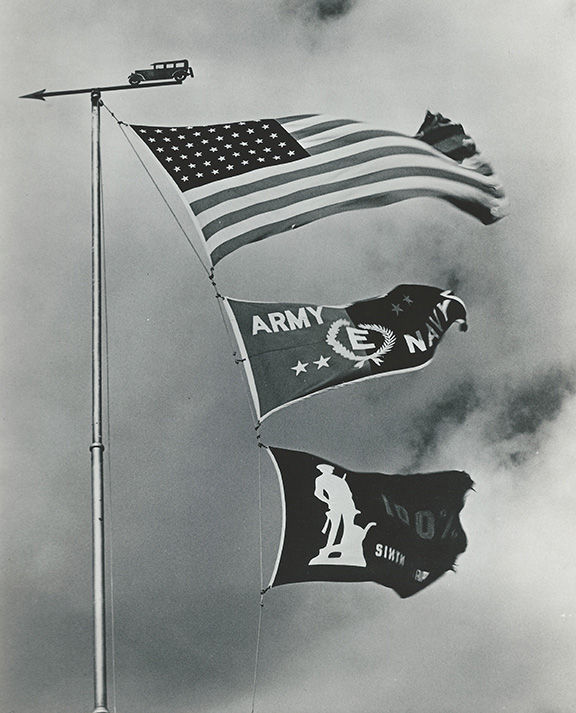

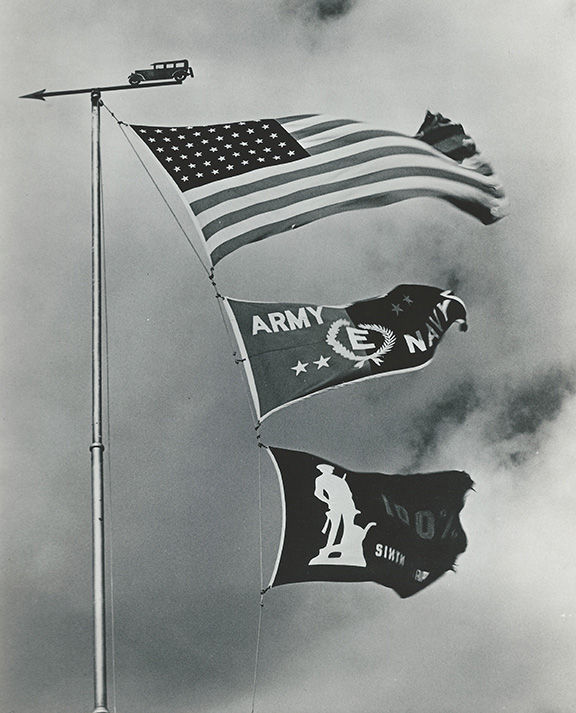

The GM Proving Grounds not only received the

Army-Navy "E" Flag but also four stars on it.

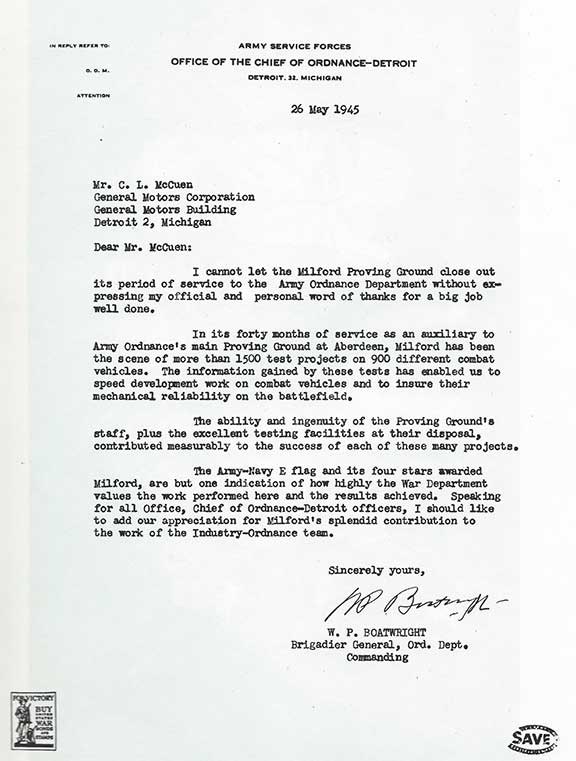

In this letter dated May 26,1945,

Brigadier General W.P. Boatwright of the Detroit Ordnance Department,

congratulates Milford Proving Ground on its four "E" star and specifies

the accomplishments of the Proving Ground to date. This included

1,500 test projects on 900 combat vehicles.

The main gate during World War Two.

Equipment tested at the GM Proving Grounds:

The GM Proving Ground was assigned over 1,500 projects on 900 different vehicles

between early 1942 and the end of the war. This was an average of

20 different vehicles tested each month.

A large majority of the armored vehicles and

trucks were built by the American Automobile Industry. Production

of these vehicles was very close to Milford.

|

Number of

military vehicles built by the American Automobile Industry

during World War Two |

|

Company |

Location |

Trucks |

Amphibious Trucks |

Tanks |

Tank Destroyers |

Armored Cars |

Self Propelled Artillery |

Other Vehicles |

Total |

| Buick |

Flint, MI |

|

|

|

2,507 |

|

|

640 |

3,147 |

|

Cadillac |

Detroit, MI |

|

|

8,592 |

|

|

1,778 |

300 |

10,670 |

|

Chevrolet |

Flint, MI and others |

281,570 |

|

|

|

3,844 |

|

|

285,414 |

|

Chrysler |

Warren, MI |

|

|

22,202 |

|

|

|

|

22,202 |

| Dodge |

Detroit, MI |

404,817 |

|

|

|

|

|

|

404,817 |

|

Fisher Body |

Grand

Blanc, MI |

|

|

13,139 |

5,855 |

|

|

40 |

19,034 |

| Ford |

Detroit, MI Area and others |

430,716 |

12,782 |

1,690 |

1,038 |

12,451 |

|

13,893 |

472,570 |

| GMC |

Pontiac, MI |

549,906 |

21,147 |

|

|

30 |

|

|

571,083 |

|

Studebaker |

South

Bend, IN |

194,535 |

|

|

|

|

|

24,924 |

219,459 |

|

Willys-Overland |

Toledo, OH |

350,349 |

|

|

|

|

|

|

350,349 |

|

Totals |

|

2,211,839 |

33,939 |

45,623 |

9,400 |

16,325 |

1,778 |

39,797 |

2,358,745 |

The 2.3 million vehicles produced by the

American auto makers during World War Two consisted of eight major types

of vehicles. They ranged in size from the 1/4 ton 4x4 command car (Jeep) up to the 46 ton M26 Pershing tank. With the exception of

Studebaker in South Bend, IN and Willys-Overland in Toledo, OH, all of

the vehicles were produced in southeast Michigan. Vehicles

designated for testing at the GM Proving Grounds by U.S. Army Ordnance

did not have very far to travel.

All vehicles and armament used by the

U.S. Army during World War Two were tested at the Aberdeen Proving

grounds in Maryland. How did Milford fit into the test program?

With 19.7 miles of roads and test tracks it could do road and endurance tests on the

different types of roads and terrain. The same type of

peacetime tests Milford performed on General Motors vehicles translated

directly into tests for military vehicles.

Chrysler leased the Packard Proving

Grounds during World War Two and Ford had its own proving ground in

Dearborn, MI. U.S. Army Ordnance directed many vehicles to be

tested at their respective company's proving grounds. However,

Army Ordnance directed many non-General Motors-built vehicles to be

tested at Milford tested during the war, as it specialized in tracked vehicles.

The GM Proving Grounds had this 25% concrete grade for testing both the

climbing and braking ability of military vehicles.

The original 1,000 acres was picked for its location

with rolling hills and flat open spaces. This provided an

excellent location for proper testing

of military vehicles.

Coming up the 25% Gravel Hill, which was part

of the durability course, is a M26

"Pershing" heavy tank. This 46-ton heavy tank may well

have been the heaviest vehicle tested at Milford. Both Fisher Body Division of GM

and Chrysler built the M26. However, this is most likely a Fisher

Body Grand Blanc-built M26. Fisher Body was the initial producer

of the Pershing and there was a rush program to get it into combat in

Europe.

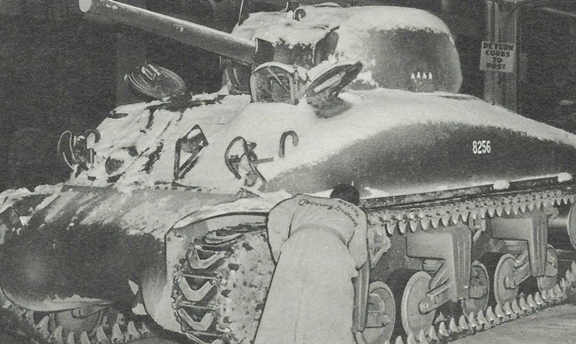

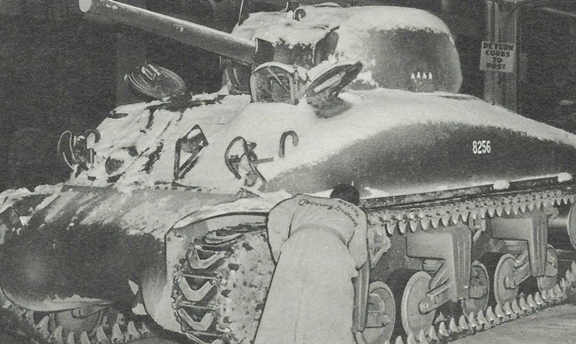

Test item 8256 is a M1A1 Sherman tank

getting a cold soak. The same tests the Proving Ground did on

civilian automobiles carried over to the military vehicles. Tests

like this made sure the vehicle could start and operate in cold

climates. The European winter of 1944-45 was one of the coldest in

recent history. The Battle of the Bulge was fought during these

cold conditions and the American military vehicles had to operate in

this hostile environment. Image added 1-6-2021.

Here are a few of the 900 vehicles Milford

tested during World War Two. Five of are fully tracked tanks

and one is a half-track. There are also armored cars and a

half-track shown.

The vehicle on the far right, of which just a

small portion can be seen, is an M5 tank produced by Cadillac and

Massy-Harris. To its left is test vehicle 8202 which is a

Chrysler-built M4A4. It can be identified by the wider than normal

spacing between the bogies. The next are two small hatch M4 series

Sherman tanks. These could have been built by any of the eleven

companies that produced this tank. These companies included the

Fisher Body Division of GM,

the Ford Motor Company, and

the Chrysler Corporation. The next Sherman in line is a small

hatch M4A1. These were not built by the American Automobile

Industry. These were manufactured by Pressed Steel, Pacific Car

and Foundry, and Lima Locomotive Works. The next two

vehicles are Chevrolet-built "Staghound" armored cars built for British Commonwealth

Forces. Next is a Ford-built M20 armored car. The last vehicle

is a half-track. These were built by the White Motor Company,

Diamond T Motor Car Company, Autocar, and the International Harvester

Corporation.

Below are contemporary photos of the vehicles

shown in the photo above. These have been restored and are owned

by museums or private owners.

M5A1 Serial Number 6297 was built by Cadillac in April 1944. Unlike the

photo, this does not have the sand shields around the upper track.

These were easily damaged and removed from the tanks once in combat

zones. Author's photo added 1-6-2021.

The next vehicle in line in the photo above

is a Chrysler-built M4A4 . Milford had several of these in for

testing during the war. In December, 1942 test vehicle number 8138

was at the Proving Ground. The example shown here is on display at the Arnhem War

Museum, Schaarsbergen

Netherlands. Photo courtesy of David Jackson, Jr. added 1-6-2021.

Another type of Sherman tank that was tested

at Milford was the prototype of the M4A6, which was powered by a

Caterpillar-built nine cylinder, all fuel radial aircraft engine.

This was at the Proving Grounds in June 1943. Only 75 of these

were built.

Starting in 1942, Pressed Steel Car Company,

located in the Chicago, IL area, had a number of its tanks at Milford

for testing during World War Two . This Pressed Steel-built small

hatch M4A1(75) is serial number 192, built in July 1942. It is USA

number 3014948. It is the oldest Pressed Steel M4A1(75) known to exist

and is owned by the Virginia Military Museum of Military Vehicles. Note

that this tank has the direct vision ports for the driver and assistant

driver. Author's photo added 1-6-2021.

Chevrolet built 2,844 T17E1 Staghound

armored cars for the British Commonwealth during World War Two.

Author's photo added 1-6-2021.

Ford built the M8 armored car during World War Two. In August1942

an M8 was at the GM Proving Ground for testing. Author's photo

added 1-6-2021.

Ford also built the M20 command car on the

same chassis as the M8. In March 1945 an M20 was at the GM Proving

Ground for testing. Author's photo added 1-6-2021.

Starting in mid-1942, International Harvester

half-tracks, built in Springfield, OH, were tested at Milford.

Author's photo added 1-6-2021.

A White-built M16 half-track with an M45

Quadmount gun turret was undergoing testing at Milford in August 1943.

Author's photo added 4-22-2021.

This 1944 photo contains five Sherman tanks,

a jeep, three M5 Stuart light tanks, and a T17E1 Staghound armored car.

An M1 10-ton 6x6 heavy wrecker is at the the far end. These were

built by both Ward-LaFrance and Kenworth. It is unknown whether

the wrecker was on-site for testing or to retrieve vehicles if they

broke down on a test track. Image added 1-6-2021.

This is a Ward-LaFrance M1 wrecker. A

GMC CCKW-353 is off to the right in this photo. Author's photo

added 1-6-2021.

The GM Proving Grounds tested a considerable

number of Sherman tanks. There are six in this photo of the

parking lot. One is either backing out or returning to its parking

place. Another is entering the lot after testing. There is

also a M24 Chaffee light tank, a half-track, and a GMC CCKW in this

photo. Image added 1-6-2021.

Below are more contemporary photos of vehicles

tested at the GM Milford Proving Grounds. Also included are

historical photos of many of the types of vehicles being tested.

Each show a different test. It should be noted that vehicles

coming to the Proving Grounds were put through a battery of tests shown

in the historical photos below.

Trucks: The Proving Grounds

tested a considerable number of Chevrolet and GMC trucks. The

jeep, built by both Ford and Willys-Overland, was also tested at

Milford.

This jeep was built by Willys-Overland.

Author's photo added 1-6-2021.

Chevrolet built 1-1/2 ton 4x4 trucks that

came to Milford for testing. Author's photo added 1-6-2021.

A number of the Chevrolet 4x4s were used as

crash trucks at military air bases. Author's photo added 1-6-2021.

The GMC 2-1/2 ton 6x6 truck was used

extensively by tactical and quartermaster units in World War Two.

Author's photo added 1-6-2021.

This GMC CCKW-352 has a water depth

indicator attached to the front of the vehicle. Image added

1-6-2021.

This CCKW is starting up the 24% grade at

the Proving Grounds. Image added 1-6-2021.

GMC also built the DUKW which was the

amphibious version of the 2-1/2 ton 6x6 truck. Author's photo

added 1-6-2021.

A GMC DUKW entering Lake Sloan for a water

test. Image added 1-6-2021.

The DUKW was purposely stopped half-way up

the 60% incline. The parking brake was then set to verify it would

hold the vehicle in place. Then the DUKW proceeded to the top of

the hill. Image added 1-6-2021.

Tanks: There were 45,623 tanks

built by Cadillac, Chrysler, Fisher Body, and Ford in southeast

Michigan. The Sherman tanks were constantly undergoing engineering

changes and improvements as the war progressed. Many of the

modifications were then tested at Milford.

Chrysler built the M3 medium tank in nearby

Warren, MI. Early World War Two tanks were riveted together.

This was replaced in later models with welded designs. The auto

industry had to develop the technology to weld thick pieces of armor

plate. Author's photo added 1-6-2021.

This shows a riveted M3 Lee tank negotiating

up an incline. Of special interest is a woman GM technician

assisting the driver of the vehicle. She was a leader in the quest

for women to do technical jobs. Image added 1-6-2021.

An M3 tank is entering the 100-foot water test. The M3 tanks were

some of the first World War Two vehicles to be tested at Milford, as it

was already in production with several manufacturers. It was

superseded in 1942 by the M4 Sherman tank. Image added

1-6-2021.

American Car and Foundry of Berwick, PA

built all of the M3 and M3A1 light tanks during World War Two. A

late model M3 light tank was at Milford in July 1942. It was a

late model M3 and very similar to this M3A1. Author's photo added

4-22-2021.

The Cadillac-built M8 75mm Gun Motor

Carriage was built on the M5 chassis. These had to undergo the

same testing at the M5. Author's photo added 1-6-2021.

Ford built M4A3 Sherman tanks at its former

Model T plant in Highland, MI. Holes can be seen along the bottom

edge of the hull above the tracks. These were for the attachment

of sand shields. Author's photo added 1-6-2021.

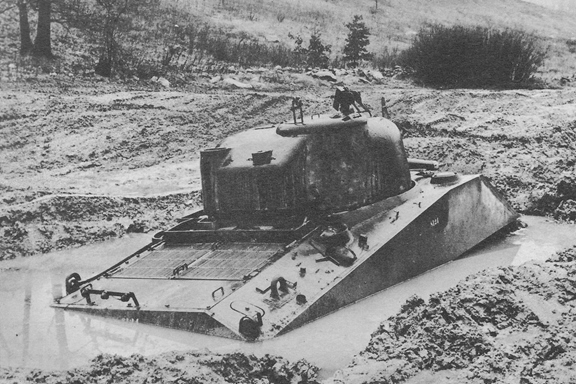

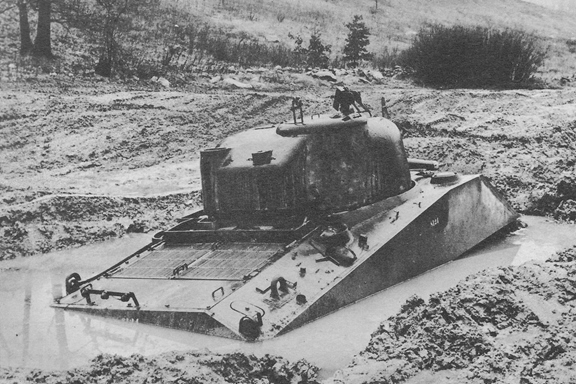

This mud test actually worked too well when

the bottom of the mud hole collapsed and this Fisher Body-built M4A2

became stuck. It had to be towed out by another vehicle.

Tanks operated off-road and when it rained, they operated in mud.

Tests like this showed the problems that operating in this type of

environment presented. As the war progressed, tracks on Sherman

tanks were widened to provide less ground pressure to operate on soft or

muddy terrain. Tests like this help to predict the effectiveness

of the proposed changes. Image added 1-6-2021.

Note that

the Ford M4A3 has its sand shields attached.

This is a Fisher Body Grand Blank-built

M4A2(75)VVSS. Milford tested a number of these. Note the

narrow track on this. Author's photo added 1-6-2021.

This Sherman tank is on display at in Victoria

Park in London, Ontario. It is the oldest Grand Blanc-built

Sherman tank in existence in the western hemisphere and is the third

oldest worldwide of all of the tanks built by Fisher Body Division of

General Motors. It is a true war veteran and is the only tank that

survived the war in operation with the 6th Canadian Armored Regiment

(1st Hussars). Due to its historical significance, I wonder why the

authorities and historians in Canada have not moved this to an indoor

venue to keep it out of the elements. It is such a shame this grand old

tank that fought all the way from D-Day to VE Day has to sit outside.

This Fisher Body Grand Blanc, MI built

M4A2(76) HVSS is a later model of the Sherman tank with wider tracks. It can be seen outside the Beatty

Street Drill Hall in Vancouver, BC. It was one of 7,508 M4A2s

built by Fisher Body. Photo courtesy of David Jackson, Jr.

The 100 foot water test was available for

testing military vehicles such as this Fisher Body-built M4A2(76) HVSS.

Image added 1-6-2021.

A Chrysler-built M4(105) was at Milford for

testing in December 1944. It was test number 8705. Author's

photo added 1-6-2021.

Cadillac and Massey-Harris both built the

Cadillac designed M24 Chaffee light tank which were tested at Milford.

Author's photo added 1-6-2021.

The hilly and rocky terrain allowed for

testing the M24's ability to negotiate this rough climb.

Image added 1-6-2021.

Lake Sloan was utilized to test military

vehicles for their fording ability. Here a Cadillac M24 is fording

four feet of water. Early in World War Two there was a severe

problem with tanks failing when entering deep water. This resulted

in re-designs to include the waterproofing of many electrical

components. Later tanks like the M24 incorporated all the lessons

learned from early war experience and tests at Milford.

Image added 1-6-2021.

Fisher Body was first into production on the

M26 heavy tank. Only Fisher Body-built M26 saw combat during World

War Two. Author's photo added 1-6-2021.

Tank Destroyers: Buick, Fisher

Body, and Ford were the only producers of fully tracked tank destroyers

in World War Two. These vehicles were similar to tanks but were

faster because they carried less armor. Milford was a prime

location to test them.

This Fisher Body-built M10 tank destroyer

was built in April 1943. It was virtually identical to the

Ford-built M10A1 with the exception of the engine. The Fisher Body

M10 was powered by two Detroit Diesel engines while the Ford M10A1 was

powered by a Ford gasoline engine. Author's photo added 1-6-2021.

This M10 is undergoing a drawbar test by

pulling six weighted General Motors trucks. Image added

1-6-2021.

Buick built the M18 tank destroyer in Flint,

MI. Author's photo added 1-6-2021.

An M18 is negotiating the obstacle climb

test at Milford. This is one test that was installed for tracked

vehicles, with no counterpart for civilian automobiles or trucks. Image added 1-6-2021.

In this test, the M18 is undergoing a

high-speed endurance test. The M18 was the fastest fully tracked

armored vehicle built during World War Two. It had a top speed of

55 miles an hour. However, at speeds this fast took a toll on the

equipment, which would become evident on the high speed track.

Image added 1-6-2021.

This was one of 300 M36 tank destroyers that

Fisher Body Grand Blanc built during World War Two. Author's photo

added 1-6-2021.

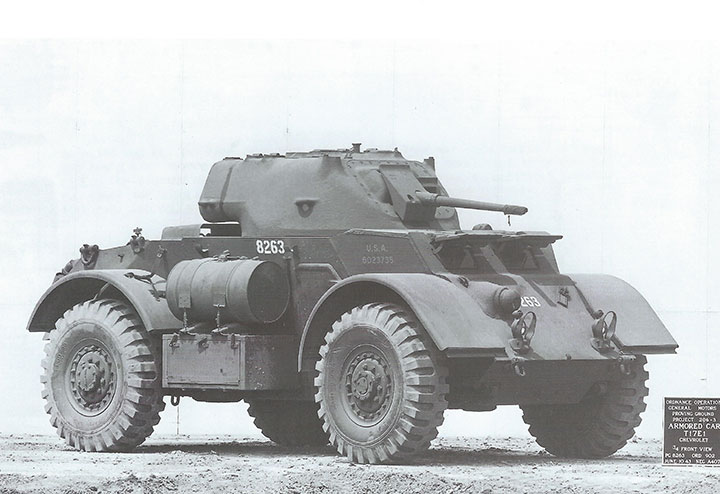

Armored Cars:

Chevrolet was the only producer of the

Staghound armored car. Author's photo added 1-6-2021.

The Staghound is undergoing an off-road

test. Image added 1-6-2021.

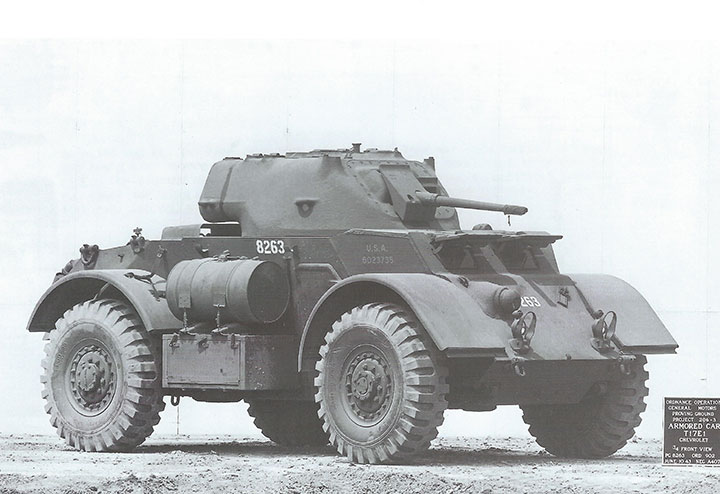

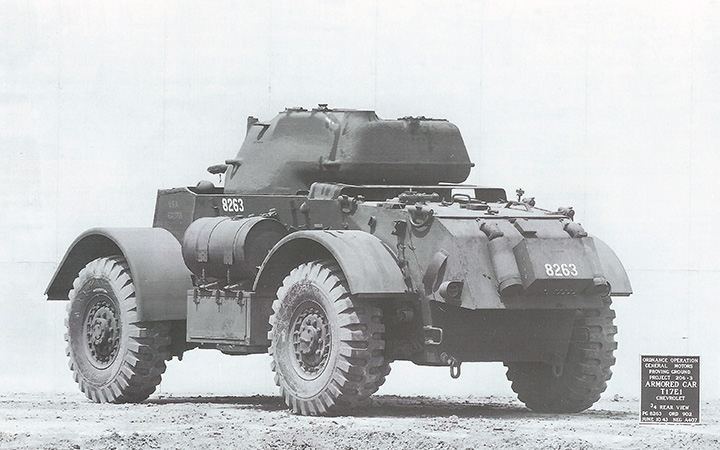

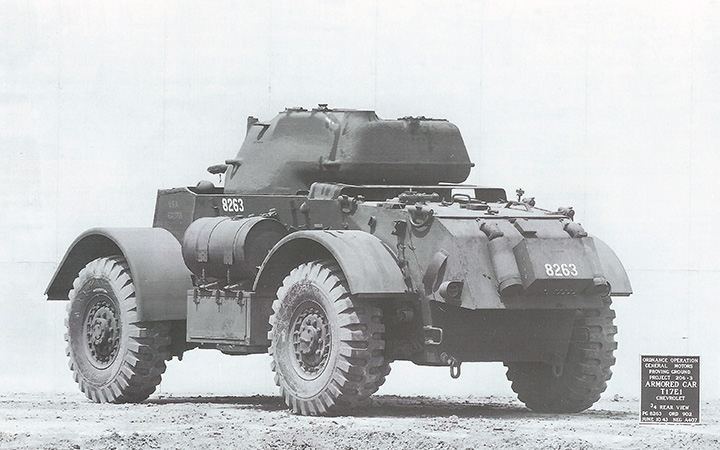

This Chevrolet-built T17E1 Armored Car

was photographed at the Milford Proving Grounds on June 10, 1943.

It was test vehicle number 8263.

This GMC- built T18E2 Boarhound was

photographed Milford on January 19, 1943. During the first

half of World War Two GMC was known as the Yellow Truck Company, as it

states on the information board.

Personal Carriers:

Studebaker was the designer and builder of

the M29 series Weasel. Author's photo added 1-6-2021.

This Studebaker Weasel demonstrated its

capabilities during an employees' family open house.

Weapons: Ten General Motors

Divisions built weapons during World War Two. AC Spark Plug,

Delco-Products, and Brown-Lipe-Chapin built .50 caliber machine guns;

Fisher Body built 90mm and 120mm anti-aircraft guns; Oldsmobile built

several types of tank guns and aircraft cannons; Pontiac built 20mm

anti-aircraft guns; Inland built .30 caliber M1 carbines; Guide-Lamp

built .45 caliber sub-machine guns; Saginaw Steering Gear built .30

caliber machine guns and .30 caliber M1 carbines. Some of these

weapons were brought to the Proving Grounds for testing.

This is an example of a Pontiac-built 20mm

Oerlikon anti-aircraft cannon. This type weapon was tested at

Milford. Author's photo added 1-6-2021.

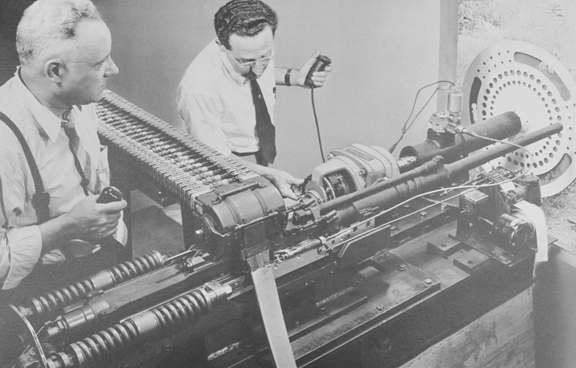

Sand is being blown onto the 20mm Oerlikon

during a test firing to verify it will continue to operate under these

conditions. This appears to be a staged photo, as the weapon does

not appear to be firing. Typical of the era, neither lab

technician is wearing safety glasses nor hearing protection.

Image added 1-6-2021.

In the back of the display case at the

Museum of the United States Air Force in Dayton, OH is an Oldsmobile M2

aircraft cannon. This one of 77,010 the division built in

World War Two. Author's photo added 1-6-2021.

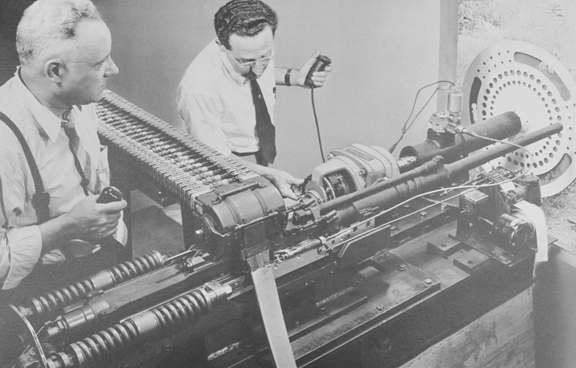

This Oldsmobile 20mm aircraft cannon is

being tested to verify it is synchronized properly to fire through the

arc of an aircraft propeller. The paper disk is attached to an

electric motor and spins to simulate an aircraft propeller. When

the gun fires, the projectiles should go through the holes in the disk

that represent the space between the propeller blades. It is

unknown for what aircraft this was being tested. There are no

known American aircraft that had a 20mm cannon firing through the

propeller arc. Image added 1-6-2021.

Guide-Lamp Division of Anderson, IN brought

its M3 submachine gun to Milford for testing. Author's photo added

1-6-2021.

|